Variable Transmission Casing

Overview

As apart of the powertrain team of UW Baja SAE, I took on the task of developing the casing of our CVT (Continuous-Variable Transmission).

Requirements

- Not take up excessive space

- Protect the transmission from dust-dirt and other substance we don’t want in the transmission

- Easy to open in case adjustments are required mid-competition

Technical Details

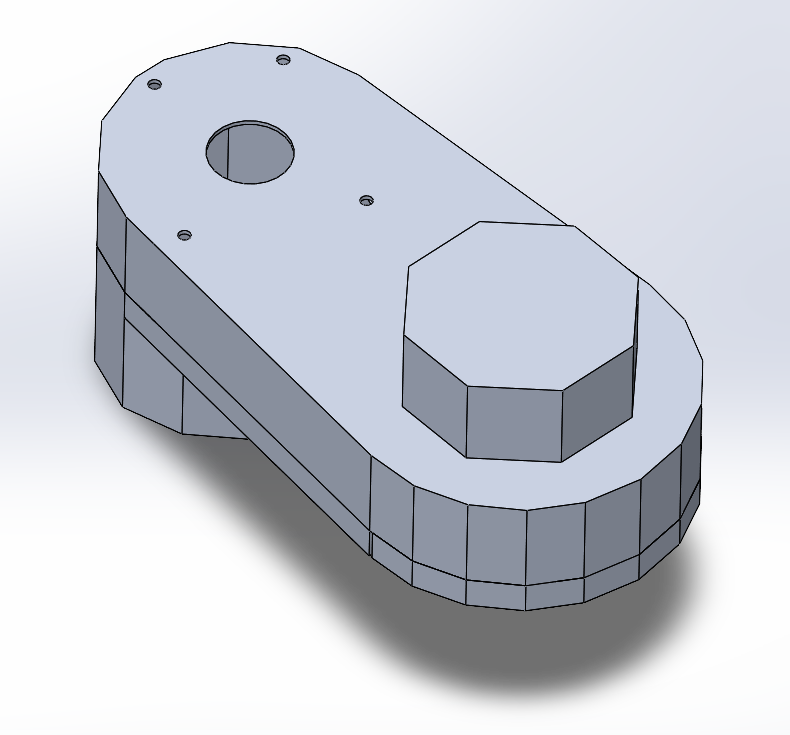

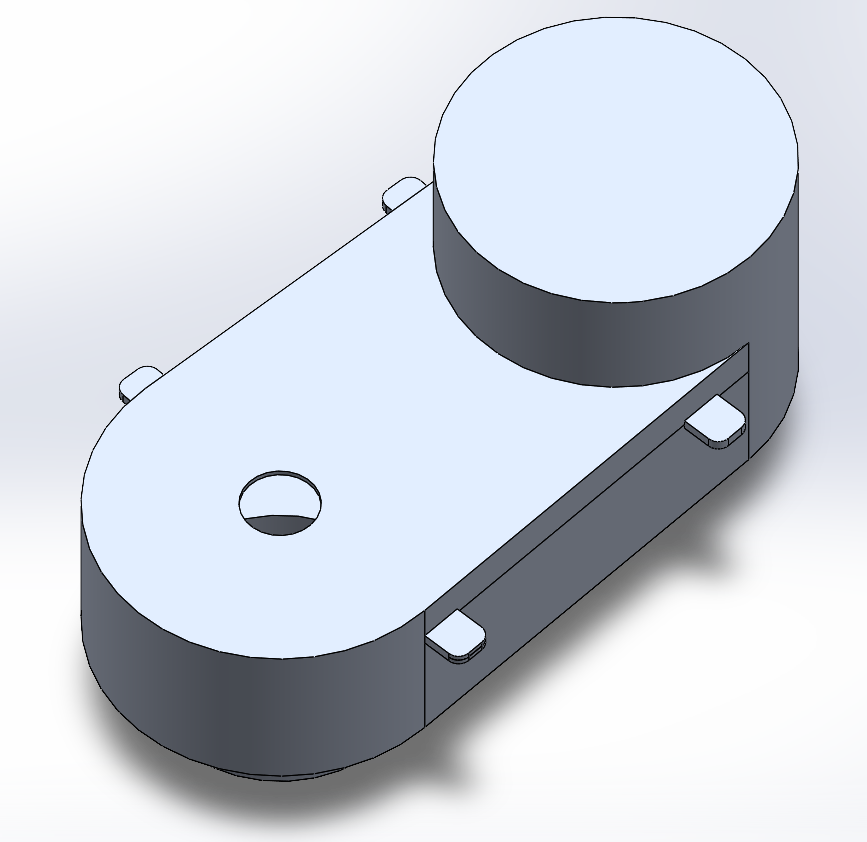

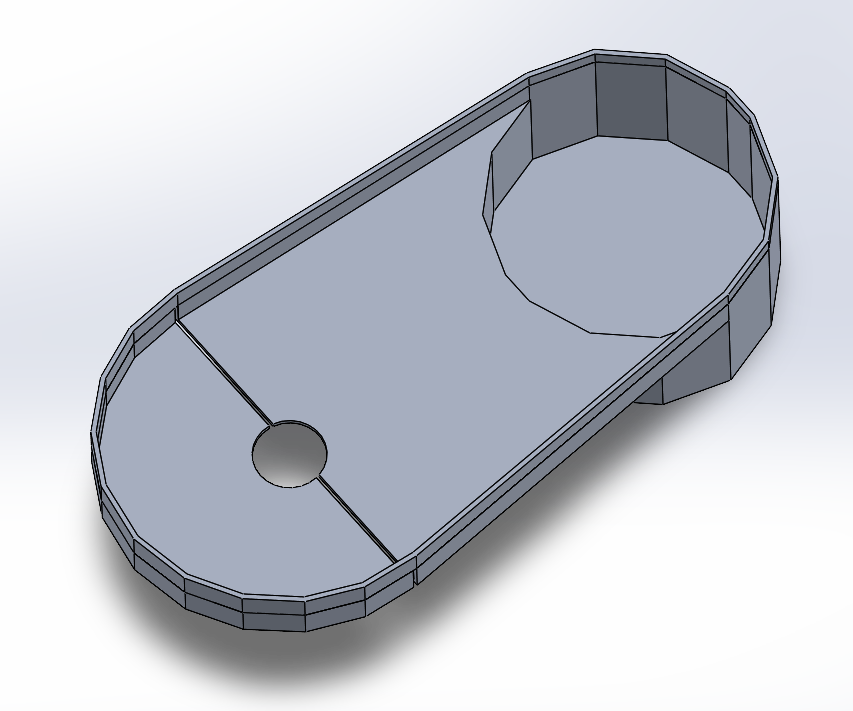

- Initial Design: Taking in dimensions of the actual CVT to be cased, as well as surrounding components and how they would link. With this information I designed the initial CVT Casing shown below split into 2 panels.

- Manufacturing Redesign: Based on the available metal fab machinery accessible to me I redesigned the casing. This included divided curved parts into multiple angled panels to be manufactured using the bender. All the different components were to be watercut, bent (if needed), then welded. I was also required to think of accessibility to the internals mid competition which is why one half of the case was split into 2 pieces around the shaft which would extrude. All the components were connected with tabs to allow easy removal during competition while still providing the required shielding from external elements.

Skills/Technologies Used

- SolidWorks

- Manufacturing (WaterCutting, Bender)